Plasticizers Explained

Plasticizers are versatile ingredients that enhance formulation consistency, stability, and texture, especially in high wax content formulas. They can resolve issues like graininess from internal migration, prevent “seeding” in butter-rich formulas, and improve thermal stability without affecting texture.

Plasticizers also reduce stabiltiy issues, offer better batch control from scale-up to production, support liquid-to-wax ratios, and ensure compatibility in complex systems

Suppress Crystallization

Fixes Graininess

Creates Creamy Textures

Supports Color Distribution

Support Thermal Stability

Stops Bloom & Syneresis

Plasticizers provide solutions for complex formulation challenges and are valuable development tools for improving a wide range of systems.

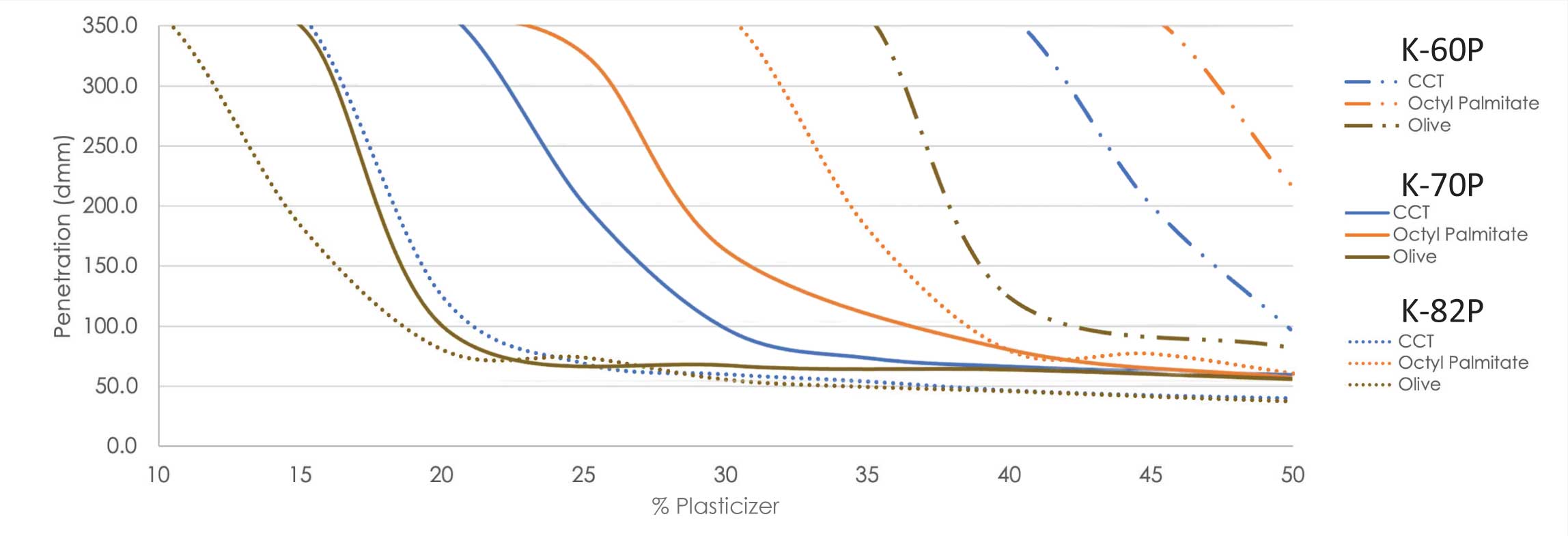

Kester Wax K-60P

Wax# 484B

INCI: Polyhydroxystearic Acid

Typical Usage Level: 1-15%

Melt Point Range: 50.0 °C – 70.0 °C

PROS:

- Suppresses Crystallization

- Improves Cushion

- Adds Creamy Texture

- Reduces Slip

- May Add Thickening

- Boosts Emulsion Feel & Gloss

- Natural Product

CONS:

- 5%> Emulsions Can Increase Tack

- Higher Usage Required

- Not Globally Compliant

- Compatibility Challenges

Kester Wax K-82P

Wax#154S

INCI: C18-38 Alkyl Hydroxystearoyl Stearate (or) Synthetic Beeswax

Typical Usage Level: 1-15%

Melt Point Range: 70 °C – 85.0 °C

PROS:

- Strong Crystallization Suppression

- Increases Melt Point

- Aids Thermal Stability

- Zero Structure

- Supports Color & SPF Distribution

- Globally Compliant

- Low Usage Level

CONS:

- 50% Synthetic

- Petrochemical Derived

NEW Kester K-70P, a natural polymer derived from Rice Wax, fills the critical gap for chemists, delivering optimal performance when Kester K-60P or Kester K-82P may not meet specific formulation parameters.

Kester Wax K-70P

Wax# 10092

INCI: C18-38 Alkyl Hydroxystearoyl Stearate (natural)

Melt Point Range: 65 °C – 75.0 °C (est)

PROS:

- Suppresses Crystallization

- Increases Melt Point

- Aids in Thermal Stability

- Better Color Distribution

- Natural & Globally Compliant